If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

About Spherical Graphite C Powder:

Spherical graphite (SPG), also known as battery-grade graphite, is a product consumed as an anode in lithium-ion batteries. The flake graphite concentrate is processed into ultra-high purity (>99.95%C) with a particle size ranging from 10 microns to 25 microns. Spherical graphite material has good electrical conductivity, high crystallinity, low cost, high theoretical lithium insertion capacity, low charge and discharge potential and flatness. It is an important part of lithium-ion battery negative electrode material and is used as a negative electrode for lithium-ion battery production at home and abroad. Material replacement products. It has excellent electrical conductivity and chemical stability, high charge and discharge capacity, long cycle life, and environmental protection. Kmpass is a trusted global Spherical Graphite C Powder supplier. Feel free to send an inquiry about the latest price of Spherical Graphite C at any time.

Specification of spherical graphite C powder CAS 7782-42-5:

Spherical graphite powder Purity: 99.98%

Spherical graphite powder APS: 8.5μm(Can be customized)

Spherical graphite powder Ash: 0.021%

Spherical graphite powder H2O: 0.08%

Spherical graphite powder S content:62ppm

Spherical graphite powder Fe content: 19ppm

Spherical graphite powder Cl content: 30ppm

Spherical graphite powder SSA: 11.79m2/g

Spherical graphite powder Tap density:0.831g / ml

Spherical graphite powder PH: 4.15

Spherical graphite powder Morphology: Spherical

Spherical graphite powder Color: black

Characteristics of spherical graphite C powder:

Long life

High-capacity

High energy density

High compaction density

Using the highest quality imported artificial graphite developed

How is Spherical Graphite C Powder produced?

Spherical graphite is produced through fine grinding, purification and sterilization. It is made of flake graphite concentrate produced from graphite ore.

Generally, flake graphite is shaped into a spherical shape by a mechanical grinding process. The round shape of graphite allows particles to be more efficiently accumulated in the LiB anode, thereby increasing the energy and charging capacity of LiB.

Then the spheroidized graphite is purified to eliminate harmful elements, including SiO2, Fe, S and other metal elements. Various purification techniques are used. These measures include the use of hydrofluoric acid for active acid purification and the use of high-temperature furnaces for thermal purification. Both methods have their advantages and disadvantages.

Active acid purification is a means and an effective purification method, but due to the nature of the acids used (including hydrofluoric acid), there are toxic and dangerous working environments and environmental management challenges. Thermal purification is an electric heating process. Compared with acid purification, it is very expensive, but it is very safe and does not affect the environment.

After purification, please use purified spherical graphite to help improve the surface area and surface area of the particles. Many LiB manufacturers use their own proprietary technology for coating.

The purified spherical graphite is then packaged into the anode shape required for LiB batteries.

Applications of spherical graphite C powder:

Spherical graphite material has the characteristics of good conductivity, high crystallinity, low cost, high theoretical capacity for inserting lithium, low charge and discharge potential and flatness. It is an important part of the negative electrode material of lithium-ion batteries and the positive electrode produced by lithium-ion batteries at home and abroad. Material replacement products. It has excellent electrical conductivity and chemical stability, strong charge and discharge capacity, long cycle life, and environmental protection. Spherical graphite is used for high-end lithium-ion prismatic, cylindrical polymer batteries.

Storage Condition of spherical graphite C powder:

The damp reunion will affect C powder dispersion performance and using effects, therefore, spherical graphite C powder should be sealed in vacuum packing and stored in the cool and dry room, the spherical graphite C powder can not be exposure to air. In addition, the C powder should be avoided under stress.

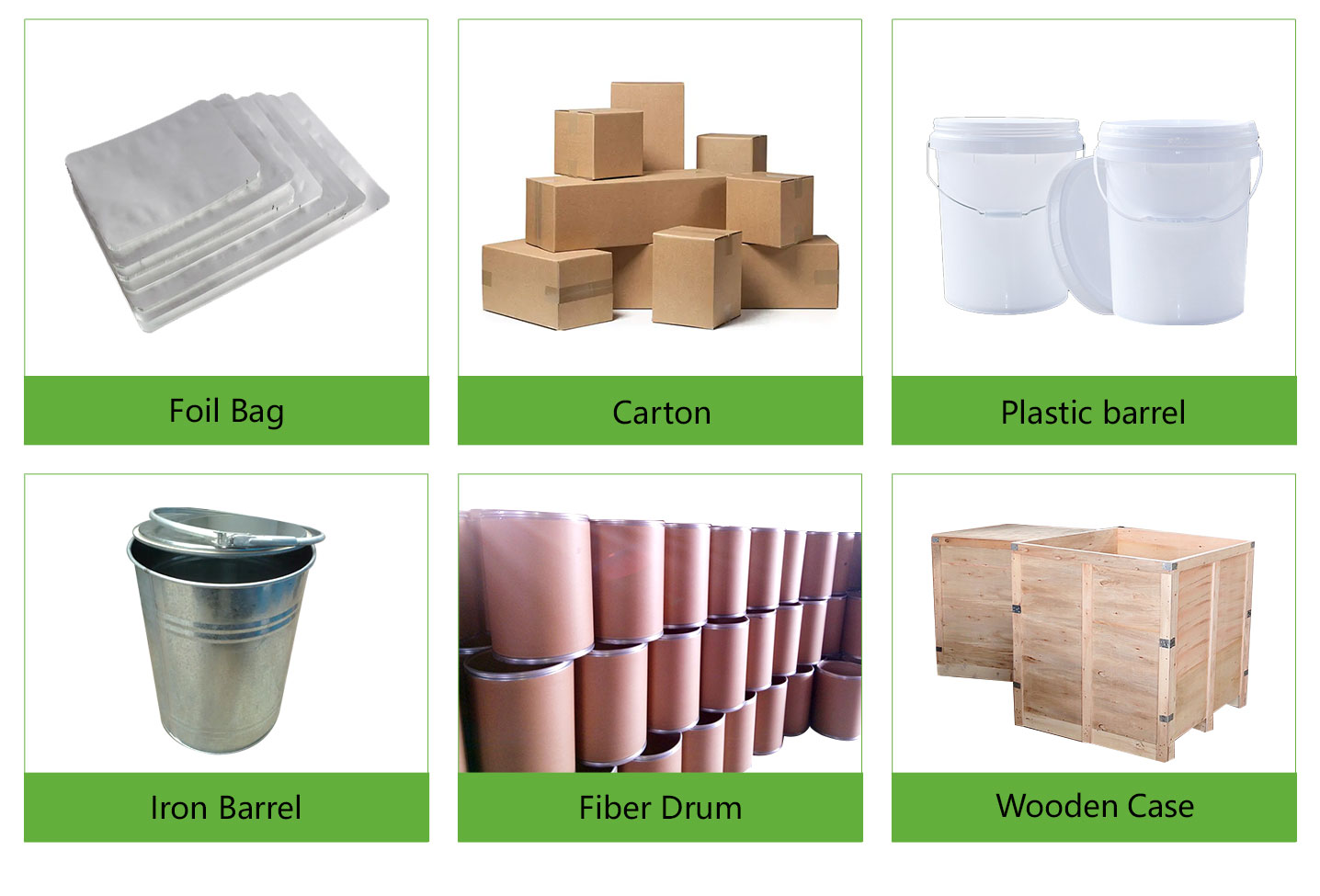

Packing & Shipping of spherical graphite C powder:

We have many different kinds of packing which depend on the spherical graphite C powder quantity.

Spherical graphite C powder packing:vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Spherical graphite C powder shipping: could be shipped out by sea, by air, by express, as soon as possible once payment receipt.

Spherical Graphite Properties | |

| Other Names | graphite powder, spherical graphite powder |

| CAS No. | 7782-42-5 |

| Compound Formula | C |

| Molecular Weight | 12.01 |

| Appearance | Black Powder |

| Melting Point | 3652-3697 °C |

| Boiling Point | 4200 °C |

| Density | 1.8 g/cm3 |

| Solubility in H2O | N/A |

| Electrical Resistivity | N/A |

| Specific Heat | N/A |

| Tensile Strength | 18 MPa (Ultimate) |

| Thermal Conductivity | 6.0 W/m-K |

| Thermal Expansion | 4.9 µm/m-K |

| Young’s Modulus | 21 Gpa |

Spherical Graphite Health & Safety Information | |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |